Comparison with the UK Version

In 2003, 2004 & 2005, Matamp USA put forth detailed

drawings, designs and the part source list for it's amp orders being made in the UK.

The hope and plan was to return amps to an old school format, and beef up the areas that

were consistently problematic with the designs coming from the UK during the 2001-2003 era.

The other primary objective was to create a line of amps

that did not change

every six months, as they had since 1993 from the Huddersfield

Shop for various reasons.

Formal paperwork was forwarded to the UK shop owner and

to his lawyers.

The lawyers had no problems, but UK Shop owner put on

led boots and everything

became literally a drag.

In the beaming light of the situation during 2004, Matamp

USA sourced it's own

speaker cabinet company in the USA known as ELECTRIC

AMP, USA.

This relieved the UK Shop of all responsibility for the

USA's speaker cabinet production.

After hours of discussions between the two Matamp outfits,

the USA amp designs were then forwarded to the UK again

in 2005.

An agreement was made between the two companies and

MATAMP USA again pre funded the new line to be made in

the UK.

The chassis agreed upon was the primary issue in order

for this agreement to work. For over 6 month's

the USA was given the affirmation

that the correct chassis were being made in the UK with

the tube spacing, roll bar

& front panel design to support the big knobs.

Most of all the gauge of steel it was to be made from.

In the final month prior to delivery, a leak in the UK

camp informed the USA owners

what was really happening with photos to support the

issues.

The voltage really hit the grid over these issues,

and the UK shop owner, Jeff Lewis scrambled with excuses.

Everything from logos, to vinyde color & chassis

format became a huge issue in

the last 30 days of the UK's production for the USA.

In August of 2005 MATAMP USA ceased all production with MATAMP UK.

Since August of 2005, Matamp USA and ELECTRIC Amp, USA

were

both ridiculed online by many Forum Wankers. So

much obvious

ignorance in action online from the forumites, it turned

the UK's "official forum" postings

into a new form of comedy to view World Wide.

Meanwhile, ELECTRIC AMP, USA trudged on with their amp

designs

and went into production in the USA. As the amps

released into the public

during 2006, the wankers online became more silent with

the occasional rant

that the USA stole it's design from the UK.

ELECTRIC AMP, USA came into bloom August of 2006 with

it's full color

spectrum catalog and wealth of it's own trademark green

vinyde for it's GREEN Amp line.

The UK shop then displayed it's new line in black Spanish

plaster vinyde,

to cover mini amps and low wattage units.

It was obvious "who built what" , and the truth of the

break

up between the two Matamp entities became quite clear.

The rumor that Matamp UK designed the ELECTRIC Amp Units is far from the truth.

Below is a photo and text illustration that will compare

the last UK Made amp that

MATAMP, USA/ Electric Amp, USA paid for next to

the USA built Electric amp unit.

THE OUTSIDE

TOP, Electric Amp USA made in the USA.

BOTTOM, Electric Amp, made by in Huddersfield

England.

The front panel layout on both units is the

very layout drawn in the

USA and forwarded to the UK several times.

Back to higher and wider

spaced E.Q. holes to provide room for the

big round knobs.

If you look close the beading on the UK version

[bottom] is smaller

on the front frame of the amp sleeve.

Hardwood Maple wood skis are used on the

USA sleeve [top].

Four rubber feet are used on the UK sleeve

[bottom].

Side: The USA made Electric Amp with one

row of piping

heavy duty corners and heat treated machine

fasteners.

BACK: USA Amp has additional ventilation

and the elimination of the 1/2 power switch.

THE FRONT

Out of the amp sleeves, the amp units chassis have only a similarity with hole placement

on the front panel. This front panel outlay was sent to the UK December 2003, and was adopted

by the UK at the expense of Matamp USA in 2005. The main purpose of the front panel change

was to get the amps back to the use of round knobs. Matamp USA wanted all big round knobs.

After the USA ceased production in 2005, the UK used this USA front panel outlay

for their new "retro" line of 80watt units in 2006.

The top of the chassis on the

UK version is the same format that Mat UK used from the Ashdown Chassis.

Placement of tranny's, filter

caps, and the rest is all found on the Ashdown

design.

This was complete opposite

of the drawings that MatUSA sent to the UK three times.

It was clearly stated, that

no USE of Ashdown,

Orange or

any other company's parts were to be used

in the Matamp USA amp production.

The USA made ELECTRIC AMP is

mounted on a 12 & 14 gauge steel chassis foundation.

The chassis are powder coated

in black like an M-16 or green to accommodate the Greenamps.

Tube space is beyond heat specification

and provides the simple application for the same

chassis to be used for the

KT88 units which require more space between glass.

UK version has INPUTS labeled

1 and 2. 2 is the HIGH [normal] input and 1 is low,

which is backward to most amps

in the industry. The input jacks are plastic Cliff brand.

The first knob reads DEPTH

on the UK version.

The knobs are hollow nylon

without a metal insert for set screw to secure the shaft.

USA Version INPUTS are

HIGH for HIGH and LOW for LOW !

Metal Military Grade Switchcraft

jacks are used for life long secure connections.

The first knob reads DEEP on

the USA version.

The knobs are solid phenolic

base, cast with a metal bushing and metal set screw.

The 1/8 inch white marker dot

is crisp .

These knobs were designed and

made in the USA for ELECTRIC AMP

and are a trademark part item

available from EA-USA.

UK version up is OFF and down

is ON ?

USA Version Where UP is ON

!!!!!!

THE BACK

Back of the chassis clearly illustrates the only similar character being that both units are 19" wide.

The back panel was provided to the UK by the USA in 2005 with a template of exact layout and text.

The original layout sent overseas is still the final back panel used on all EA-USA amp units. [right]

The UK shop went on with engraving old back panels that had the half power switch and 6 jacks. [left]

Placement of tranny's tubes and caps are totally different.

The UK version tranny's mount at the back edge of the chassis which creates a lot of stress on

the chassis. Tubes are right between two hot tranny's and their roaming current.

This and other non-shielded engineer formats induces the "frequency noise" hum & drone

from the 2001-2005 era Matamp UK units.

From left to right, the rocker switch is suppose to put the amp from full to half power.

The Slave out with the level is one of 3 things the UK did according to the

design and agreement the USA provided them. The double speaker jacks

are in continuation of the previous 2003-05 UK version. This area became

the hot issue in the USA as from the UK factory the output tranny's were typically

wired wrong and the OHM loads were frequently 8-8-4 instead of 16-8-4.

The back panel on the UK version bows out, from the lack of needed adhesive

and a better fasteners.

The basic and clean back panel design that was submitted to the UK several times.

The USA version has 2 Fuses, Slave out and slave level control

and 3 metal, military grade output jacks to expel the output of the MM tranny's.

The TUBE Space was very important to the USA design. Typical usage of high wattage

amps are for pure "performance" and heat is an issue. The EA-USA design

is beyond specification between the tube glass which permits more space for heat dissipation.

Also, this permits the same chassis to be used for the larger KT88 valves used by EA-USA.

Chassis depth is larger on the UK's Ashdown

chassis used at Matamp UK.

Dual output jacks and the use of plastic

Cliff jacks are found on the UK version.

Here is the PC Board Dual Output

Jack assembly on the UK Version.

If you look close the back

of the chassis you will see the back of the chassis is tweaked

from the weight of the transformers.

This is super common, on the

UK amps, and something that Mat Mathias himself

got away from in 1968 when

he ended the S2000

folded aluminum chassis

and went to a heavy gauge welded

steel chassis on the GT's.

This un-road-worthy chassis

was a problem for Matamp USA from 2001 until it ceased

production with the Huddersfield

shop in 2005.

Hours of reforming tweaked chassis,

and remounting new

plex gave MAT-USA enough hands

on experience to have no

desire perpetuating thin gauge

chassis.

The Electric USA version has

one dedicated output jack per ohm load setting.

Metal Switchcraft Pro Audio

Jacks with the correct frequency elimination washers

are used, like Ampeg, SUNN

and Fender used in the late 60's and early 70's.

Solid worthy connections with

a jack that is easily serviced is ideal for long life on Pro Audio gear.

The UK transformers are so far back that

they touch the interior of the amp sleeve.

This is a heat line up that promotes, noise,

short tube life and tranny failure.

Again, the USA version has

NO half power switch.

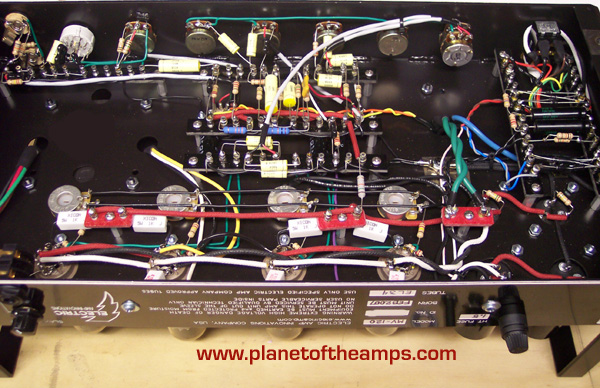

INSIDE :

The UK version has a piece of sheet aluminum taped to the bottom of the chassis.

It was the UK's version of Faraday shielding that is as FUBAR looking as it is function.

The holes must be made in the

UK with the scissors that cut the tape to

hold the chassis shield.

Offset and torn punctures that could

be made more accurate with

an old AK at 100 yards.

The tape was always disturbing

to the USA team, and was something was

not continued with the ELECTRIC

AMP Units and was definitely not part of

their drawings forwarded and

agreed upon with the UK.

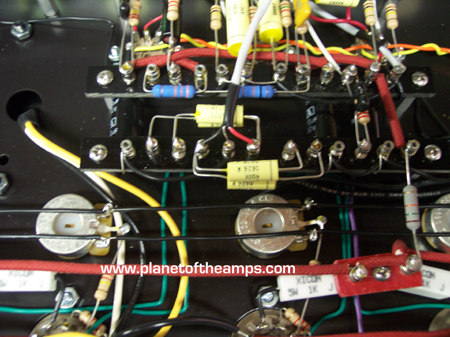

Inside the UK amp, you can

see the multi-level Printed Circuit boards and stranded wire assembly.

This is for certain a 180 in

comparison to the USA Military Grade Hardwire format.

Dave Green never would draw

or supply schematics and the interior changed every shipment.

The UK could never supply service

drawings/schematics, so Matamp USA had to first

draw them out and have their

own drawings on hand for future repairs. To date the

only record of the inside of

these amps is kept in archive in the USA. Jeff Lewis was

never involved with ANY of

the actual amplification production from 1993-2005

for Matamp USA with the exception

of the amp sleeve.

Dave Green designed, built and

formatted most of Mat UK's products from his Ashdown origins.

Looking at his works you can

see he is a precision engineer.

Cooped Upstairs in the Huddersfield

Shop,

loaded down with heaps of stress

designing, engineering, hands on constructing amps.

The UK shop seemed tightly guarded

with information only because they didn't really

have any on hand. Most of it

was in Dave's head.

l

Inside the USA ELECTRIC built

unit it is simplistic, and solid.

18 gauge Hardwire and solid

double Turrets are used, with placement of components

in a very specific manner to

optimize quiet audio frequency, and maintenance.

The turrets on the UK version

are not pressed, they are form molded into PC board.

The issue of printed circuits

with turrets mounted on top contradicts the design and

doubles the length of each

circuit path. In essence the long way around the amp

for the power to travel.

Precise hardwire and turret

layout with top of the line SOZOtm components.

Turn the amp units upside down, and you must

first get a block of wood to

support the UK amp to prevent the tubes from

being crushed.

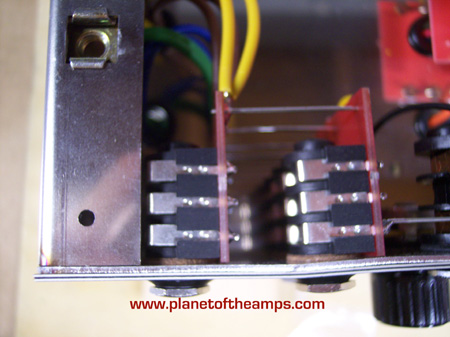

The USA version [right] chassis has a mounted

roll bar set that

provides two functions. 1. Chassis Strength,

2. Easy Maintenance.

Upside down the USA built Electric Amp stands

FREE, and avoids crushing

the components on top of the chassis.

With the EA-USA chassis you can set it on

any of it's six sides and it will stand free.

The unit is uniform and balanced.

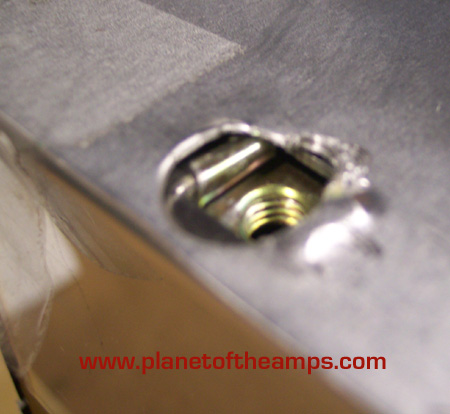

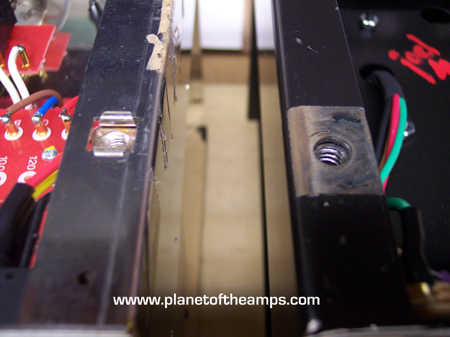

Securing the chassis to it's

amp sleeve was a problematic issue for the UK units.

The UK chassis on the left

utilizes a rectangle hole with a cage nut.

These cage nuts yank out of

the rectangle hole when mounted in the sleeve.

Once the cage nut releases

from it's hole it spins on the end of the screw

which creates a new can of

worms.

The USA chassis on the right

has a heat treated grade nut welded to the interior of the chassis.

Once bolted into the sleeve

the chassis will not suffer internal damage.

These are upgraded chassis

screws made in the USA used to replace the similar

screws supplied from the UK

. Better than the stock ones supplied by

the UK, but still not the right

fastener for a 50+ pound amp unit to be secure.

5/16 Heat Treated bolts with

1/2 heads and heat treated washers are used to

secure the ELECTRIC AMP chassis

that is made in the USA.

The same type of bolts are

used in late 60's and early 70's muscle cars to mount

cylinder heads, intake and

exhaust manifolds.

Ridiculed as "over-kill", but

if you look at a spec sheet for fasteners and the

weight distribution, they are

the right bolt for the job.

This comparison of the UK and USA built ELECTRIC Amp units should clarify

a lot of the rumors found online.

Both amp are great sounding amp units. The UK amp

is a cool amp,

but FAR from what was agreed upon and paid for by the

USA company.

With the help of Dave Green and John Tilley the "first

and last" 14 UK Electrics were

completed in the USA. Both John and Dave

were under peculiar pressure within the walls

of the Huddersfield shop, which ultimately created their

departure from Matamp UK also.

Replacement parts and insight were provided by Dave to

the hands doing the repairs and refabs

after the amps arrived in the US. At this stage

of the relationship between MatUK and MatUSA,

Jeff Lewis was eliminated from the equation in June of

2005.

Jeff's concerns were not invested in amp building, but

the creation of Matamp's next

release, which was a pamplet claiming "Matamp at 60".

This was a wild contradiction

since Matamp was not a 60 year old company as it was

created by Mat in 1958 and

was promoted for almost a decade from 1997-2005 by Matamp

USA as "Since 1958".

The vast divide between the two companies was made more

evident and simple

upon the release of this false titled UK booklet in 2006.

The USA amp company was interested in "building" and playing

amps.

The UK amp company was more interested in "talking" about

amps

and staking claim on the efforts of their main financial

funding from MatUSA .

Over 1000 Units Pre Paid by Matamp USA made them

the largest product consumer in the UK shop and accounted

for 90%

of Matamp production from 1993-2005. MatUSA held

the trademark at

the time, and was responsible for most of Matamp's sales

and service.

Jeffrey Lewis left this fact out of his 12 year premature

booklet "MATAMP at 60" in 2006.

Three years later in 2008 ELECTRIC AMP USA continues to

perpetuate

a strong line of hand made tube amps and pro audio speaker

cabs World Wide.

EA-USA remained the owner of ALL Amp Color Logos that

were

previous trademarks of Matamp USA.

Matamp USA and Matamp UK are two seperate entities.

MATAMP UK is again under re-organization.

The people involved with Matamp UK during it's second

wind

[1993-2005 post Mat Mathias] have all fled from the shop

and it's affiliation.

John Tilley left during December 2005 to open his own

shop.

Dave Green left in October 2007 "forever" he boldly states.

Rumor has it from Jeffrey's gal Dizzy, they are going

to

have a "new product line out for 2008".

RETURN

all rights reserved - www.planetoftheamps.com